AluPrime3 (AP3) Body Technology

Nothing is more flexible...

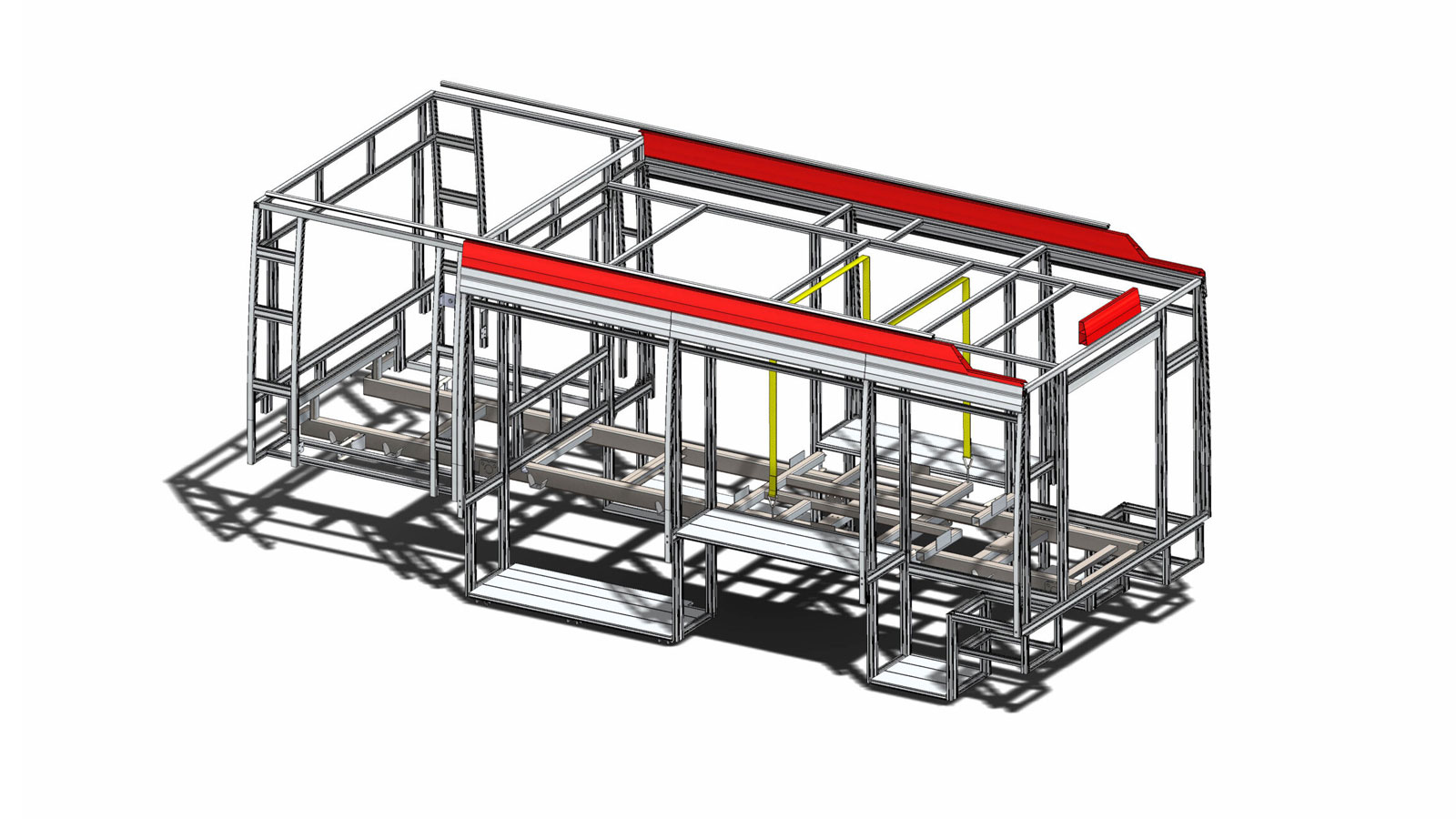

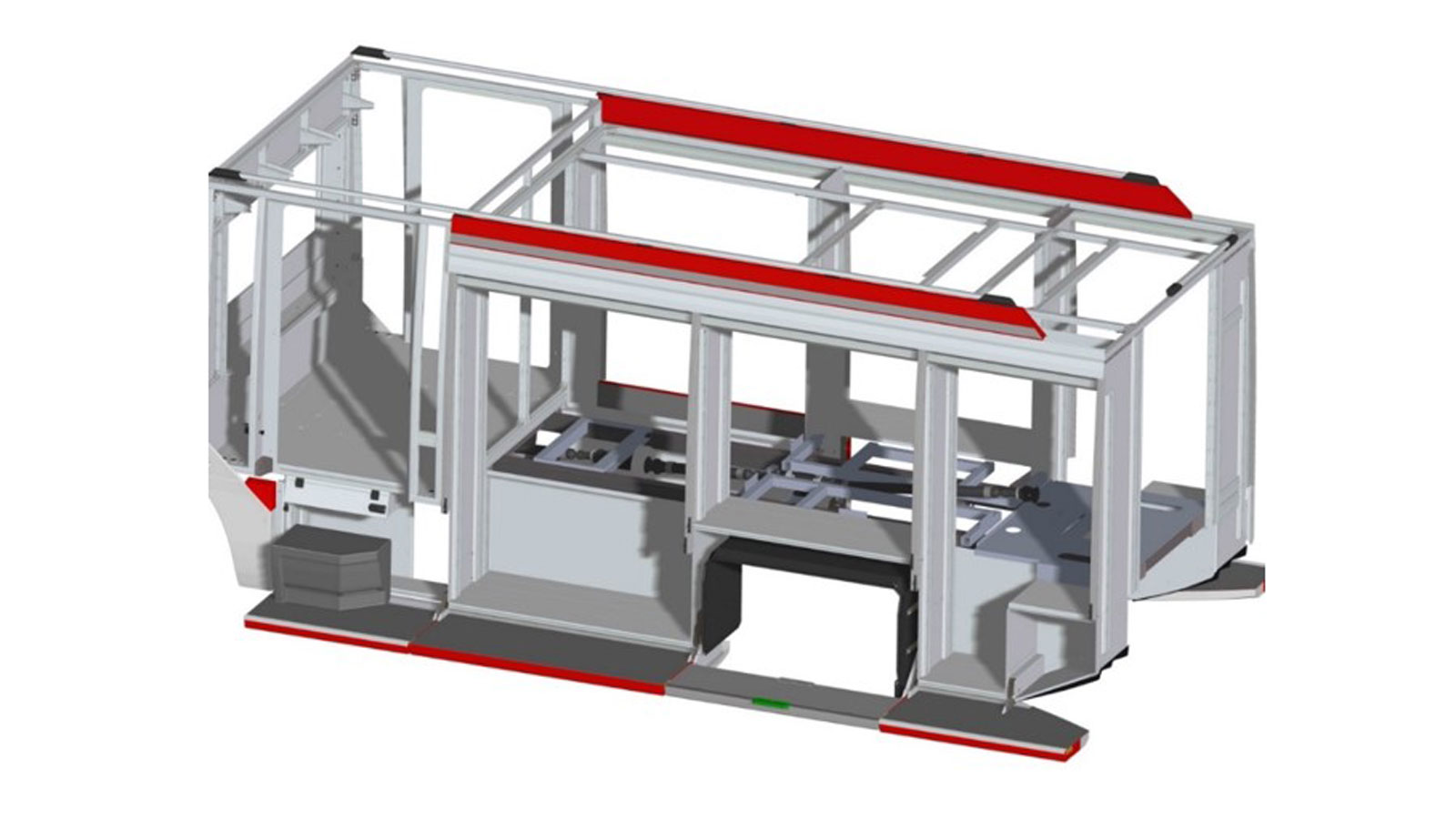

The new ITURRI superstructure technology

consists of anodized aluminum profiles bolted together and thus offers maximum flexibility for individual expansion requirements.

The extremely stable superstructure is also designed to withstand the highest dynamic loads and is around ten percent lighter than the previous version. By simply exchanging profiles, the new ITURRI "AP3" can be easily retrofitted or converted.

From the outside, the "AP3" is distinguished by the cambered body shape - this also enables a smooth transition to the driver's cab with an unchanged space volume. The side sheeting is made of aluminum, which is firmly bonded to the "AP3" structure and thus gives the body additional stability. The sheets are powder-coated, ensuring a particularly robust and scratch-resistant surface quality.

The durable and robust subframe is the connecting element between chassis and body and has been completely revised. The AP3 body is deep-drawn between the axles (equipment compartments G1 and G2) and behind the rear axle (equipment compartments G5 and G6).

In the upper area, the equipment compartments are closed by powder-coated roller shutters (spring-shaft assisted) and in the lower area by hinged steps with completely new hinges including maintenance-free gas springs.

The equipment is stored on pull-outs or swivel walls. On request, a flap can also be provided at the rear (GR equipment compartment) for the pump control station as weather protection for the operator (optionally also with integrated roller shutter).

The crew compartment is integrated into the body work. The connection to the driver's cab is via a generously dimensioned cutout with bellows.

If desired, the breathing apparatus can be arranged in the seats either in or against the direction of travel. Storage space is provided under the folding seats to accommodate firefighting equipment.

In addition, they have a mesh compartment accessible from the front for storing personal items.